Made in the USA: End-to-End Guide to Developing Your U.S. Manufacturing Footprint

Intel is investing billions in new semiconductor fabrication in Ohio. In the last five years, Eli Lilly has committed over $50 billion to expand its U.S. manufacturing footprint, announcing plans to build four new domestic sites in 2025. Apple has pledged more than $600 billion to expand its U.S. manufacturing operations over the next four years. Titans in technology, pharmaceuticals, and automotive are rapidly growing their domestic footprints.

“Made in the USA” is regaining momentum. Once a symbol of pride — or skepticism — the phrase now reflects a strategic shift toward domestic manufacturing. Companies are rethinking offshore strategies in response to global tensions, political shifts, rising overseas costs, regulatory hurdles, and hard-earned lessons from pandemic-era supply chain disruptions.

Recent policy changes — tariffs, deregulation, tax incentives — have accelerated this trend. Billions are being invested in U.S. facilities across industries, signaling renewed confidence in American manufacturing.

As companies evaluate where to expand, the U.S. deserves a fresh look. What’s driving industry leaders to choose American soil?

In this series, our multidisciplinary team explores the key considerations: supply chain strategy, site selection, government incentives, build-vs.-buy decisions, financing, permitting, energy, cybersecurity, and workforce development. At this pivotal moment, we’re here to help businesses lead the way — building smarter, stronger, and more resilient manufacturing in the U.S.

CLICK GEAR TO INTERACT

Manufacturers have all-around business needs.

Foley offers the end-to-end business solutions manufacturing clients need. From protecting the IP of your initial bright idea to siting and facility development, through your manufacturing process, going to market, and any after-sale issues, our attorneys have seen it and done it.

Initial Product Concept & Development

- Patent, Trademark & Trade Secret Strategies

- Technology Acquisition & Licensing

- Regulatory Assessment, Planning & Compliance

- ESG Considerations

Siting & Facilities Development

- Siting Strategies & Land Acquisition

- Nearshoring & Government Incentives

- Facility Planning & Construction

- Tooling Agreements

- Environmental Permitting

Supply Chain Management

- Direct and Indirect Procurement & Supply Agreements

- Supply Chain Resilience & Redundancy

- Import & Customs Compliance

- Supplier Relations & Disputes

- Distressed & Bankrupt Suppliers

The Manufacturing Process

- Labor Relations, OSHA, & Employee Benefits

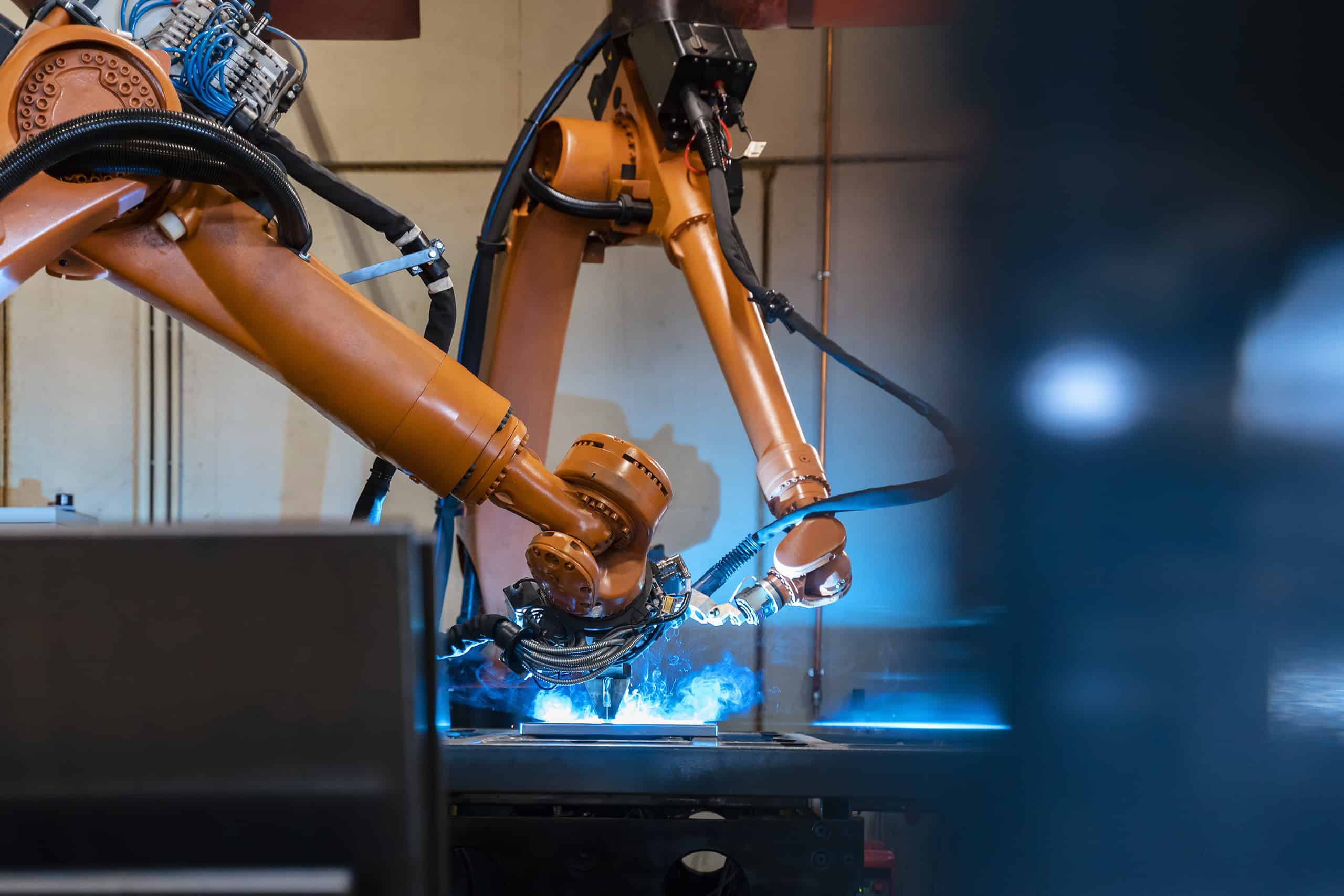

- AI, IoT & Robotics

- Cybersecurity & Data Protection

- Sustainability & Product Stewardship

- Emission & Effluent Compliance

- Risk Management & Insurance Issues

Going to Market

- Antitrust, Pricing & Competition Issues

- Distribution, Network & Retail Strategies

- Government Contracting

- Export, National Security & Customs Compliance

- CPSC, FDA & Regulatory Compliance

- Packaging, Labelling & Advertising

- Terms of Sale, Warranties, KPIs & Liability Management

After the Sale

- Product Recalls

- Privacy, Data & Analytics

- Warranty Disputes

- Product Liability & Class Actions

- Recycling & Product End-of-Life

- Patent, Trademark & Trade Secret Enforcement