The Auto Industry’s Talent War: Winning the Race for Skilled Workers

For over a century, the automotive sector was defined by mechanical engineering, fabrication, and assembly line mastery. But today, the industry is undergoing a technological transformation so profound it is rewriting the DNA of car manufacturing. The shift toward electric vehicles (EVs), autonomous driving, and AI-enabled and other technology driven systems has turned automakers and suppliers into competitors in a new kind of battleground — one for highly skilled technology talent.

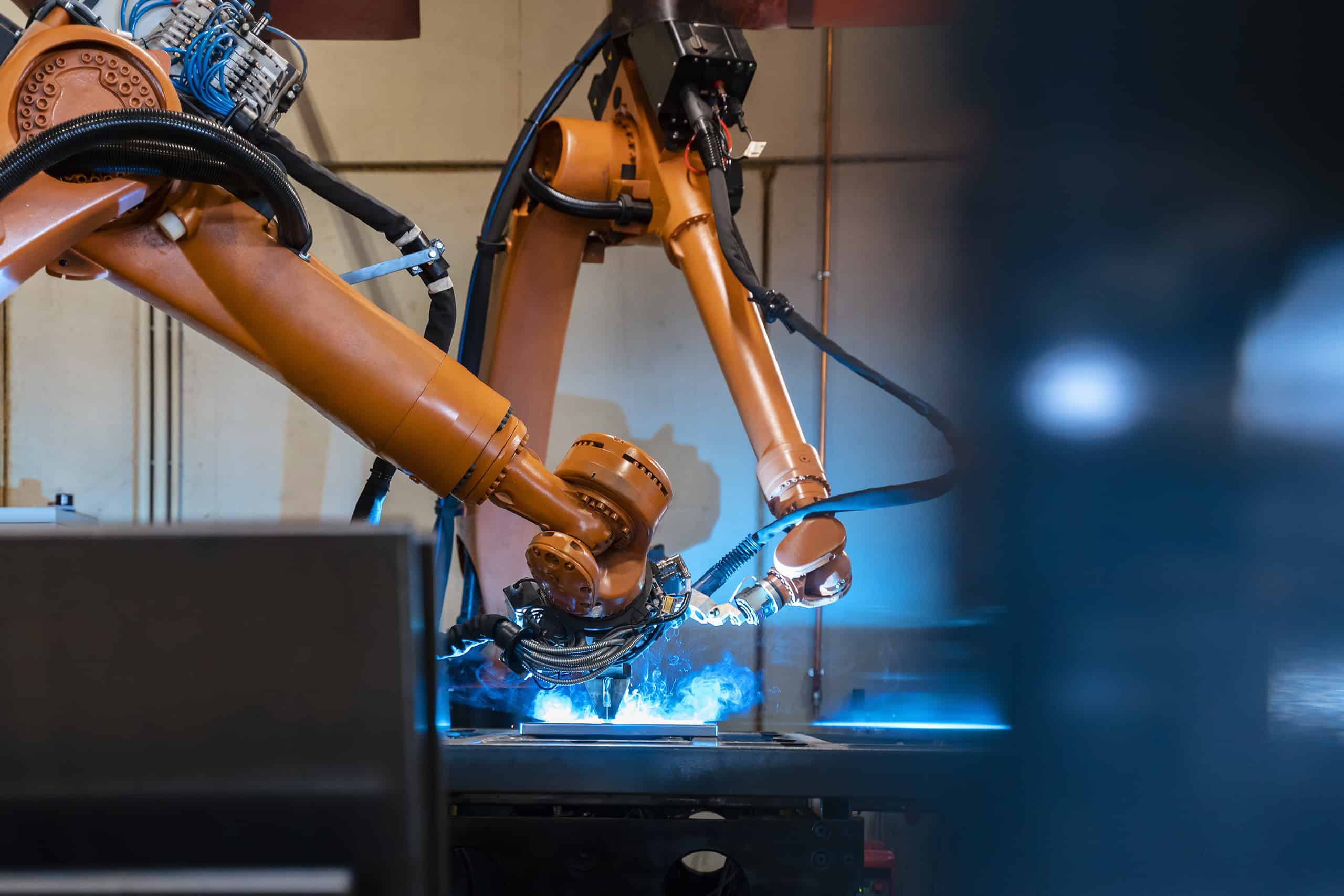

While robotics and automation have long been present on the assembly floor, the integration of complex software systems, machine learning algorithms, and AI-driven quality control has raised the stakes. Car companies are no longer just competing with one another; they are vying against Silicon Valley giants, AI startups, and tech-forward industries that already have pipelines for rare digital and technical expertise. For OEMs and suppliers, the race is not just about building the car of the future, it is about finding the people who can make that future possible.

Part I – Why Automotive Companies Can’t Fill Their Technical Roles

Despite the perception of abundant college graduates, the reality is a mismatch: there are not enough candidates with the specific skills the automotive industry requires at this moment. According to a survey report by Arthur D. Little and MEMA, “labor is the binding constraint on U.S. manufacturing viability and a competitive disadvantage.”[1]

Over the past few decades, a societal push toward four-year degrees has inadvertently reduced the volume of skilled trade workers entering the workforce. This makes it exceedingly difficult for automakers to fill crucial hourly production jobs. Historically, these roles were feeder positions into manufacturing careers, but fewer workers are prepared, or willing, to take them. The result is a shortage of the very people needed to operate advanced manufacturing lines.

More challenging still is the skills gap in automation, technology advancements, and AI. In modern automotive plants, AI systems aid in predictive maintenance, supply chain optimization, and quality inspection. However, these systems do not run themselves—they require a workforce trained not only in programming but in data analytics and machine learning applications unique to automotive environments. For example, a recent manufacturing study conducted by Deloitte Consulting LLP and the Manufacturing Institute (the “Study”) indicates that there has been a 75% increase in demand for simulation and simulation software skills over the past five years. But many of these competencies are far more common in technology hubs like San Francisco or Austin than in traditional manufacturing regions, leading OEMs and suppliers to compete for talent with tech giants whose compensation packages and work environments set high expectations.

This has created a secondary bottleneck: the engineers, data scientists, and AI specialists needed for autonomous vehicle development are scarce. According to the Study, the skills gap and shortage of qualified applicants could lead to over 1.9 million manufacturing jobs going unfilled within the next decade. Without sufficient workforce to fuel innovation, the industry risks slowing its trajectory toward the future it has already promised consumers.

Part II – Strategic Responses: Building the Automotive Talent Pipeline

Higher salaries alone will not solve the human capital challenge in the automotive sector. Companies need to reinvent how they attract, train, and retain people—starting far earlier in the career lifecycle. Below are talent development and attraction strategies that some automotive companies have started using and have seen success with.

1. Start Early: Build the Talent Pipeline in High School

Recruiting highly skilled technology talent can no longer begin after candidates enter the job market; hiring efforts must start by inspiring career interest in this specialized area at the formative stage. In other key manufacturing-driven economies, this student-to-employee pipeline is formalized. Specifically, Germany adopted the “Verbundausbildung model, where businesses collectively take responsibility for training the next generation of apprentices.”[2] Japan, Korea, Mexico, and China have similar programs in which industry is involved in the pre-hire training process. Id. In the U.S., where such a structured training pipeline does not exist, automotive companies may find success by engaging directly with high schools and community colleges — not just through job fairs but by hosting STEM-focused workshops, plant tours, and interactive demonstrations of how automation and AI function in the modern car-making process. These activities demystify highly technical roles and make them aspirational for young students.

2. Meet Gen Z Where They Are

Today’s emerging workforce lives and networks online, meaning recruitment strategies need to leverage the same platforms they use to learn, socialize, and job hunt. Social media campaigns showcasing a company’s technology, sustainability efforts, and career opportunities can spark interest among digital natives. Video content highlighting cutting-edge EV projects or autonomous-driving labs can convey both the skillsets needed and the excitement behind the work.

3. Offer More Than Paychecks—Sell the Culture and the Lifestyle

Recruitment has shifted from a purely financial transaction to one in which intangible benefits matter greatly, particularly among the next generation of workers. Potential employees, especially younger ones, want to know about company culture, career growth opportunities, and the lifestyle they can enjoy outside of work. For example, some Michigan employers have tailored talent recruitment efforts to market the “Pure Michigan” lifestyle — including proximity to lakes, recreational activities, and the growing cosmopolitan appeal of Detroit. By aligning talent attraction with local identity and quality of life, companies can differentiate themselves from geographically scattered competitors.

4. Partner With Community Organizations for Recruiting and Training

Local trade organizations, workforce agencies, and school placement teams are untapped assets for many OEMs and suppliers. These partnerships can provide access to pools of potential candidates and allow for collaborative training initiatives. For instance, community colleges and technical education centers could run co-designed certificate programs in EV systems diagnostics or industrial AI, creating ready-made talent streams that feed into local manufacturing roles.

5. Increase Hiring and Retention Through Internships and Mentorships

One overlooked aspect of talent strategy is ensuring that recruitment and hiring efforts have a lasting impact. This means closely analyzing the effectiveness of programs aimed at increasing conversion rates of internships and apprenticeships into full-time positions. It also entails building mentorship programs that give new and prospective employees a sense of connection and clear growth paths within a company, which can help develop loyalty and establish long-term career trajectories. Fostering loyalty, career advancement, and a sense of belonging at a company are critical and may be the deciding factor for wavering candidates and employees, as businesses compete against each other and may try to lure workers with lucrative offers.

6. Consult with Counsel Regarding Talent Acquisition and the Use of AI in Recruiting

Companies benefit from consulting with legal counsel on methods for identifying candidates with highly technical skillsets and AI expertise, and on structuring total compensation packages that are likely to attract and retain highly sought-after talent. Counsel are well-positioned to offer best practices and/or training about the use of AI in hiring practices. Companies should be mindful of the legal risks associated with using AI in the recruiting and hiring process, including the risk of unintended discrimination from third-party AI screening tools, which may expose them to liability under federal and state laws.

Securing the Sector’s Future

The automotive industry sits at a turning point. EV adoption and autonomous driving are no longer distant possibilities; they are active engineering and manufacturing challenges unfolding in real time. Success in this era will be determined by the ability of OEMs and suppliers to secure and cultivate a workforce fluent in both hardware and software, capable of bridging traditional mechanical know-how with next-generation digital capabilities.

This means reframing the definition of “automotive worker” to encompass AI specialists, data analysts, robotics programmers, software engineers, high-tech maintenance technicians, and cybersecurity experts — roles previously associated with technology firms rather than assembly plants. And it calls for an evolution in education strategy: not just waiting for universities to produce graduates, but directly shaping curricula, influencing career ambitions, and offering training that is specific to automotive technology.

In many ways, the automotive talent war mirrors the historical labor battles of the industry’s early days, when production lines reshaped manufacturing employment. Today, that battle is fought not over the physical assembly line, but over digital innovation, machine intelligence, and the minds capable of bringing these systems to life.

The companies that win will be those that start early, think creatively about recruitment, and treat talent development as a core strategic priority — not a secondary HR task. In an industry as competitive and fast-moving as automotive, the true horsepower remains human.

[1] Arthur D. Little & MEMA Original Equipment Suppliers, 2025 Report, Turbo Charging U.S. Automotive Manufacturing Competitiveness – Strategic Levers to Transform Supplier Capabilities (last visited Nov. 30, 2025), https://www.adlittle.com/sites/default/files/2025-11/ADL%20US%20automotive%20manufacturing%202025.pdf.

[2] Arthur D. Little & MEMA Original Equipment Suppliers, 2025 Report, supra.